Are you in the market for new equipment? Maybe your eyeing a shiny new flatbed printer that promises 1000 sq. ft. per hour? Or you’re shopping letter benders to bring production in-house?

Purchasing new equipment could help your business grow, but it could tank your cash flow and end up costing you much more than just the cost of the equipment.

So how can you be sure you’re actually making a good business decision when purchasing new equipment? Here’s a few tips to ensure you’re making the right equipment moves as a sign shop owner.

The buying backstory

I co-host a podcast for sign shop owners so I get to have a lot of interesting conversations with sign industry folks every week.

We get a ton of encouraging feedback from listeners, but every once in a while we get emails that raise larger questions.

We’re huge fans of outsourcing certain products and services to trusted partners. And we’re very vocal about “having the work” before you even think about spending a lot of money on new equipment.

Recently we had someone write in and tell us thanks for helping them justify a decision to buy an expensive flatbed cutter they wanted for several years.

They took a single thirty-second comment out of context from an hour long episode about outsourcing. The comment was about “a flatbed cutter going hand-in-hand with a flatbed UV printer”. And they apparently used it as justification to move forward with a very expensive business purchase.

I’m all for growing and improving your sign shop. Helping others in the industry is the biggest reason we do the podcast. But this encounter really got me thinking about the bigger picture and how purchasing decisions are made within our industry.

Outsourcing vs producing in-house

This is the classic debate: should you produce in-house or outsource to specialists? While bringing production in-house with new equipment may seem appealing (increased control, potential cost savings, and faster turnaround times), it's important to remember that it also brings with it additional responsibilities.

For example, maintaining equipment, training staff, and dealing with any potential problems that arise with the new equipment. Moreover, the investment required for new equipment can be substantial. On the other hand, there’s plenty of great wholesale providers for almost every type of sign or graphics imaginable.

Outsourcing can give you flexibility and allow you to take advantage of their specialized knowledge and equipment. Granted it can sometimes come with higher costs and longer lead times.

The best approach depends on your specific situation. So, rather than following trends or competitors or just listening to what you think you want, carefully analyze your business, your clients' needs, and your capacity before deciding.

Don’t make an emotional decision

I’m not here argue with you – I know you’ve done your research. I’ve gone through the same process myself many times.

You’ve compared all the competitive printers and their pricing.

You read all the specs and reviews you could find online.

You asked everyone on the Facebook group that had the same printer for their feedback.

You’ve looked at your sales numbers, profits, and cash flow to make sure you can afford it.

This all feels logical and we just “know” we’re making a sound decision. But science tends to disagrees with you and I.

Research actually shows most of our purchasing decisions are made emotionally – not rationally.

Harvard Business School professor Gerald Zaltman says that 95 percent of our purchase decision making takes place in the subconscious mind. [HBR]

It’s only AFTER we’ve made this emotional decision does our rational side of brain kick in to help us justify the decision with logic. Damn you science! Stop getting in the way.

But just being aware of that fact can help you can avoid making a poor financial decision for your shop. So now’s the time to dig deep and ask yourself – why do you really want this new equipment?

Here’s a few examples of what I consider weak reasons to buy new equipment.

This equipment will expand our capabilities.

This is the next logical step for our growth.

One of our competitors has similar equipment.

XYZ shop is killing it right now and they have this equipment.

The best advice I can give here is sit with the decision for a bit. It’s easy to get excited about what a new piece of equipment COULD do for your business. When you start to feel that excitement – wait a while before you act. A few days, a few weeks, or even maybe a few month for the excitement to wear off so you can evaluate it rationally.

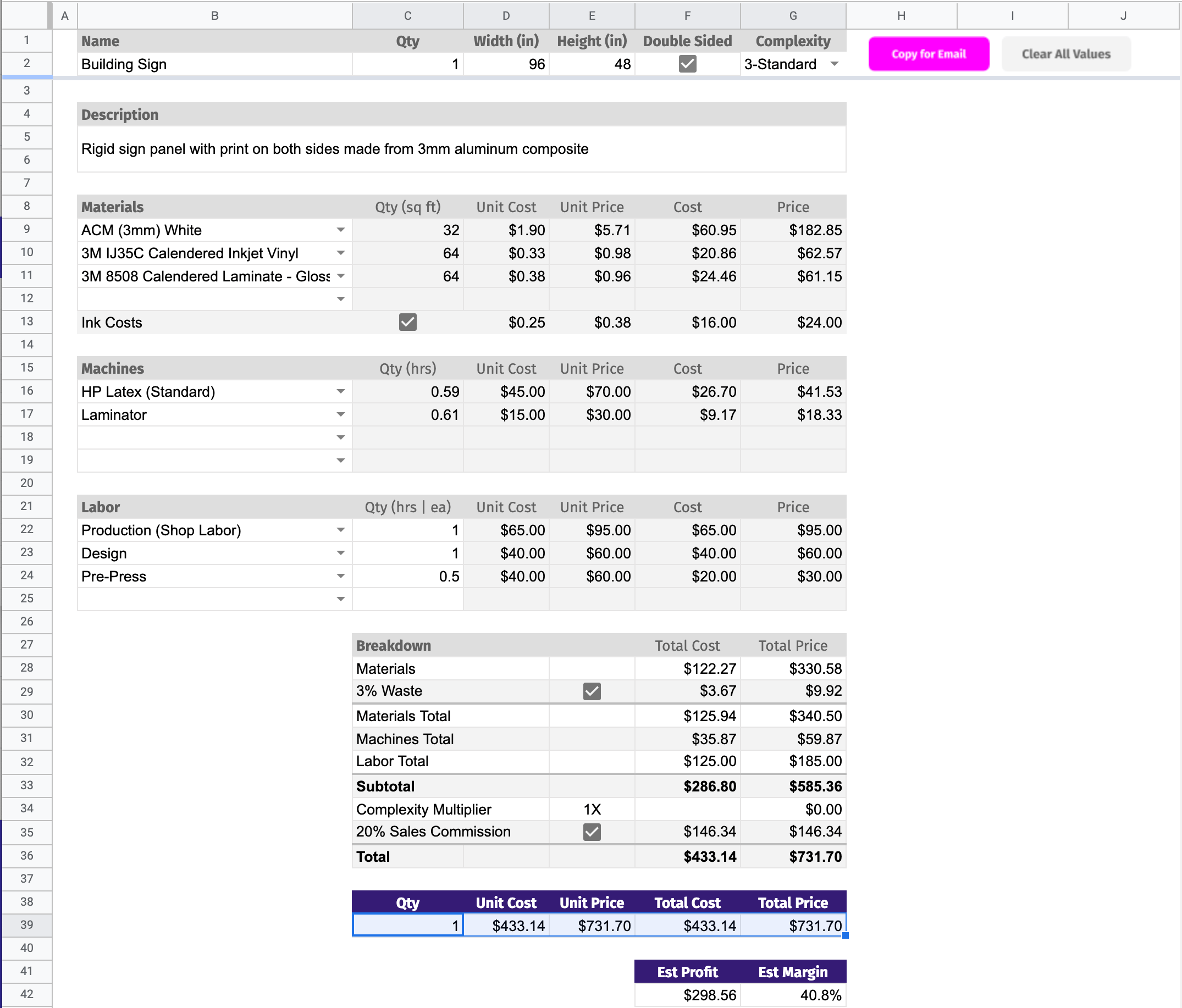

Actually run the numbers on your ROI

I realize I’m making a lot of assumptions for you here.

This new equipment will save you time and / or money.

You fully understand your shop’s financials.

You can “afford” to make the payments on this equipment without endangering your cashflow.

You’ve consulted with your accountant to confirm this is a smart decision.

You’re going to make a “real” return on your investment in this particular equipment.

But a lot of shop owners miss crucial parts of the ROI equation when considering a new equipment purchase. They forget to take into account the time, effort, and money it takes to learn how to use, maintain, and eventually replace the new equipment.

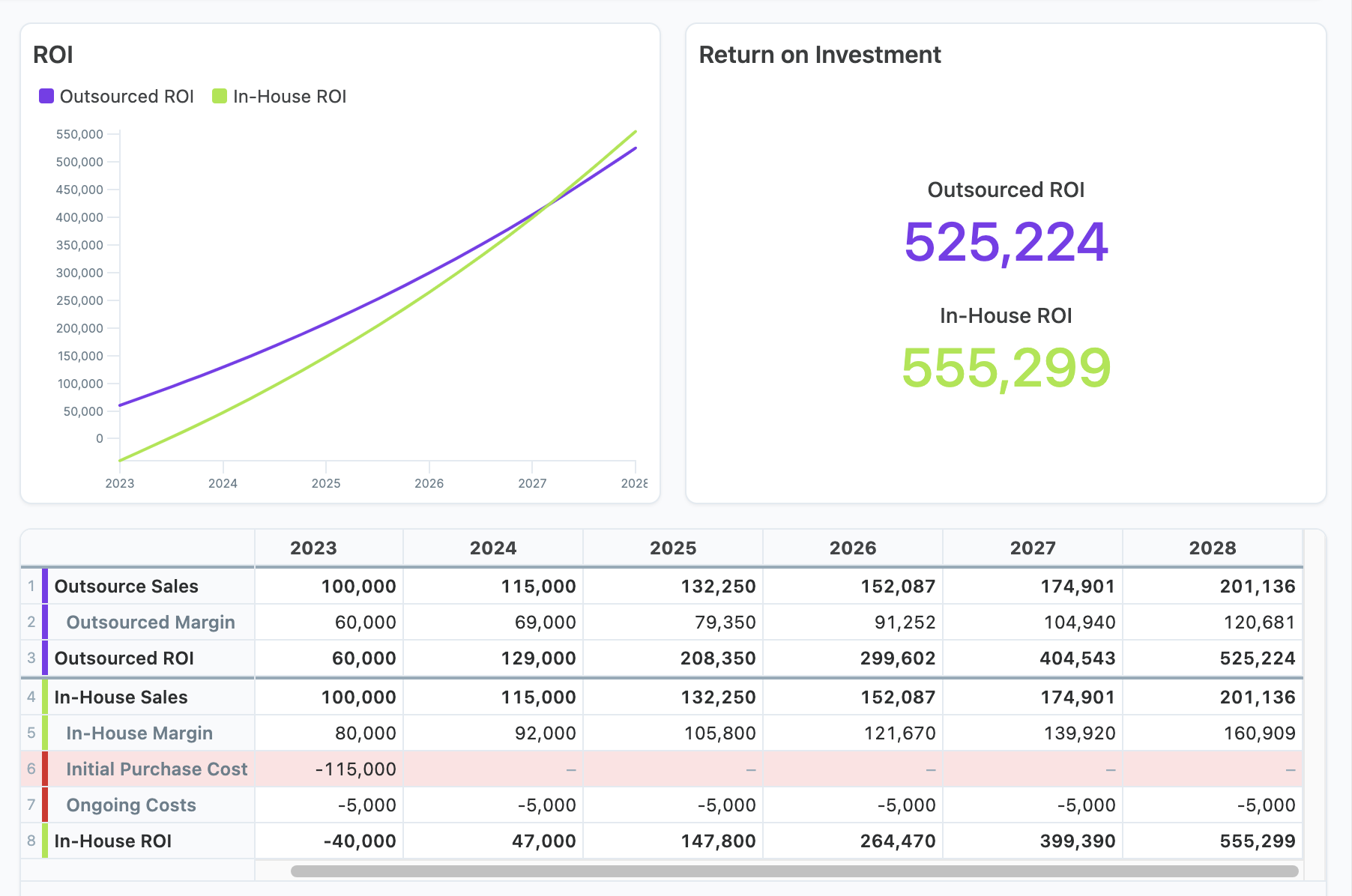

Using some math - we’ll actually illustrate why you may be better off outsourcing.

Buying a flatbed printer

Let’s assume your currently outsourcing about $100k worth of sales for flatbed printing with a 15% growth rate year after year and your current costs of goods sold are 40%. And you’re eyeing a new flatbed printer that costs $115k installed that should help you cut your costs of goods sold in half to 20%.

Let’s review our numbers.

Outsourced

Sales of Flatbed Printing - $100k

Estimated Sales Growth Year over Year - 15%

COGS - 40%

Buying

Purchase Cost - $115k

Maintenance Cost - $5k per year

Sales of Flatbed Printing - $100

Estimated Sales Growth Year over Year - 15%

COGS - 20%

As you can see by the chart - the ROI from buying the equipment doesn’t extend the ROI from outsourcing until year 5. Put another way – it would take over 5 years to see a justifiable return. And by then the equipment is probably obsolete.

Your net return for buying this equipment vs outsourcing would be roughly $30k divided over 5 years (or $6,000 per year).

Given those numbers, it doesn’t seem worth it because this model doesn’t even factor in the salary of the person to operate this equipment 🤦. The only way to shorten your time to positive ROI would be to tremendously increase your sales of flatbed printing.

Have a real plan for making profit

I’ve heard many sad stories from shop owners where equipment that was purchased to “expand our capabilities” ended up sitting in the corner of the shop unused and taking up space. Instead, before making any large investments, you should have a clear plan for how the new equipment will generate profit. Break this down into actionable steps instead of leaving it as some pie in the sky goal.

Purchasing new equipment can help a business grow, but it can also be a costly mistake. To avoid this, sign shop owners should consider outsourcing certain products and services to trusted partners, run the numbers on the ROI of the equipment, and have a plan for making a profit from the equipment.